October 02, 2025 – PRESSADVANTAGE –

Parfuse Corporation, a recognized leader in specialized aluminum processing, is reinforcing its support for Long Island manufacturers by providing aluminum heat-treating services to communities such as Garden City, Hempstead, and Mineola. This focus is intended to strengthen local partnerships and improve access for manufacturers seeking high-performance aluminum components that require enhanced strength, durability, and reliability.

For more than 50 years, Parfuse Corporation has provided advanced aluminum processing solutions to industries that operate under stringent performance requirements. Its heat-treating service is a critical step in optimizing aluminum alloys for aerospace, defense, automotive, medical, and electronics applications. By supporting regional manufacturers more directly, the company ensures that properly treated aluminum parts can be incorporated into production workflows with greater efficiency and reliability.

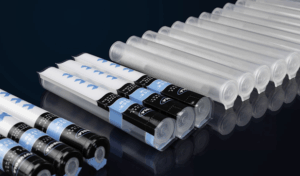

Heat treating of aluminum is a controlled thermal process that alters the microstructure of the metal to achieve desired mechanical properties such as increased hardness, improved tensile strength, and enhanced wear resistance. The process also improves the alloy’s ability to withstand extreme operating environments without deformation or premature failure. This makes it an essential step in the manufacturing of components that must meet strict technical and regulatory standards.

The process requires precise temperature control and timing to achieve consistent results. At Parfuse Corporation, heat treating cycles are carefully tailored to the specific aluminum grade and the end-use requirements of the component. By following strict process parameters, the company ensures that each batch of parts achieves the intended strength and durability specifications, while preserving critical tolerances for complex designs.

Parfuse Corporation’s Westbury facility is equipped with specialized ovens, precision temperature monitoring systems, and quality control tools designed for aluminum heat treating. Its technical team brings decades of expertise in selecting the right treatment cycles for different aluminum alloys, balancing performance improvements with the preservation of dimensional integrity. Each part undergoes rigorous inspection to confirm compliance with applicable standards, ensuring readiness for integration into client systems without rework.

Strengthening access to Garden City, Hempstead, and Mineola provides logistical advantages to local manufacturers. Reduced transportation times help lower handling risks, while closer proximity encourages collaboration between production teams and engineering staff. This integration supports smoother project scheduling and allows potential adjustments to be made earlier in the manufacturing process.

Heat treating provides advantages that directly impact product performance across multiple sectors. In aerospace, treated aluminum components are able to withstand high stress loads, vibration, and rapid temperature changes, which are common in flight-critical systems. In automotive manufacturing, the process improves the durability of structural and mechanical parts, reducing wear in high-friction environments and contributing to safer, longer-lasting vehicles. For medical equipment, heat treating ensures lightweight yet strong aluminum components can perform with precision and reliability in critical care situations. In electronics, heat-treated aluminum parts support conductivity and resistance to thermal stress, protecting sensitive assemblies from performance failures.

The reliability of heat-treated components depends not only on the process itself but also on strict adherence to quality standards. Parfuse Corporation maintains detailed records of every treatment cycle, conducts thorough post-process inspections, and performs multiple forms of testing, including hardness verification, dimensional analysis, and surface integrity checks. By maintaining this level of oversight, the company ensures uniformity across every batch, eliminates risks of premature wear, and guarantees that each product is delivered ready for use without additional modification. These efforts reflect Parfuse’s broader commitment to compliance with aerospace and defense industry standards, as well as the expectations of medical and automotive manufacturers.

Industry observers consistently identify heat treating as a vital part of aluminum component manufacturing. Without this process, parts may fail to achieve their intended strength and durability, leaving them vulnerable to premature wear or structural breakdown. Parfuse Corporation’s long history in aluminum processing provides clients with the confidence that their components will perform reliably, even in the most demanding environments.

The company’s ongoing mission is to strengthen manufacturing capabilities across Long Island by providing advanced processing solutions close to where they are needed. By combining proximity with technical expertise, Parfuse Corporation supports the region’s competitiveness in industries that depend on specialized aluminum components.

Heat treating is also a process that benefits from collaboration during the early design phase. By working with manufacturers before production begins, Parfuse Corporation can advise on material selection and treatment plans that maximize performance while reducing the risk of delays. This proactive approach helps ensure compatibility between design requirements and thermal processes, resulting in components that meet strict standards for function and durability.

With aluminum heat-treating services accessible in Garden City, Hempstead, and Mineola, Parfuse Corporation anticipates greater opportunities to collaborate with local manufacturers on projects ranging from small prototypes to full-scale production runs. The company’s ability to manage both custom orders and high-volume demands makes it a flexible partner for businesses of all sizes.

As industries continue to evolve, the need for reliable, high-quality aluminum processing remains constant. Parfuse Corporation’s combination of experience, advanced equipment, and commitment to quality ensures that clients receive components that perform to the highest standards. By reinforcing local partnerships and maintaining strict process discipline, the company continues to play a central role in supporting specialized manufacturing across Long Island and throughout the nation.

###

For more information about Parfuse Corporation, contact the company here:

Parfuse Corporation

Don Paris

(516) 997-8888

support@parfuse.com